Micro Energy Harvesting

Energy Harvesting gains increasing interest as a potential energy source for sensors and sensor networks that are currently been developed, e.g., for monitoring of environmental parameters, of industrial facilities or buildings. Often, these sensors are used in remote locations with difficult access, where battery change is not desired and too expensive. As an alternative, energy harvesters generate electrical power from the energy of their environment. Accessible energy sources are, for instance, wind, light, vibration and temperature differences. The research activities concentrate on energy harvesting systems based on magnetic shape memory alloys (SMAs) and other thermomagnetic materials that make use of either vibration energy or waste heat.

Thermal energy harvesting with ferromagnetic SMAs

Ferromagnetic SMAs show a martensitic phase transformation and a ferromagnetic transition at the Curie temperature TC. Both effects cause abrupt, strong changes of magnetization that are used here for energy harvesting. The operation principle is shown in Figure 1. A SMA cantilever of Ni-Mn-Ga of 2 x 4 mm2 in lateral size and 10 µm in thickness is fixed at its back end to a substrate. A movable mass of additional ferromagnetic material is mounted at the front end. The cantilever is deflected by a miniature magnet located above, as the magnetic attraction force exceeds the reset force (Figure 1a). A heat source is placed next to the magnet, which heats the cantilever, as soon as it touches the heat source. When reaching the phase transformation temperature, the thermal shape memory effect leads to an increase of the reset force FAustenite. In addition, the magnetic attraction force strongly decreases when the Curie-temperature is reached (Figure 1b). Both effects cause a reset motion of the cantilever in its initial position and thereby a temperature decrease. Thus, periodic heating and cooling results in an oscillatory cantilever motion. A coil is positioned at the cantilever end such that the moving mass dives into the coil during reset motion. Thereby, the magnetization change in the coil induces an electric current, which can be used to charge a battery.

|

|

|

|

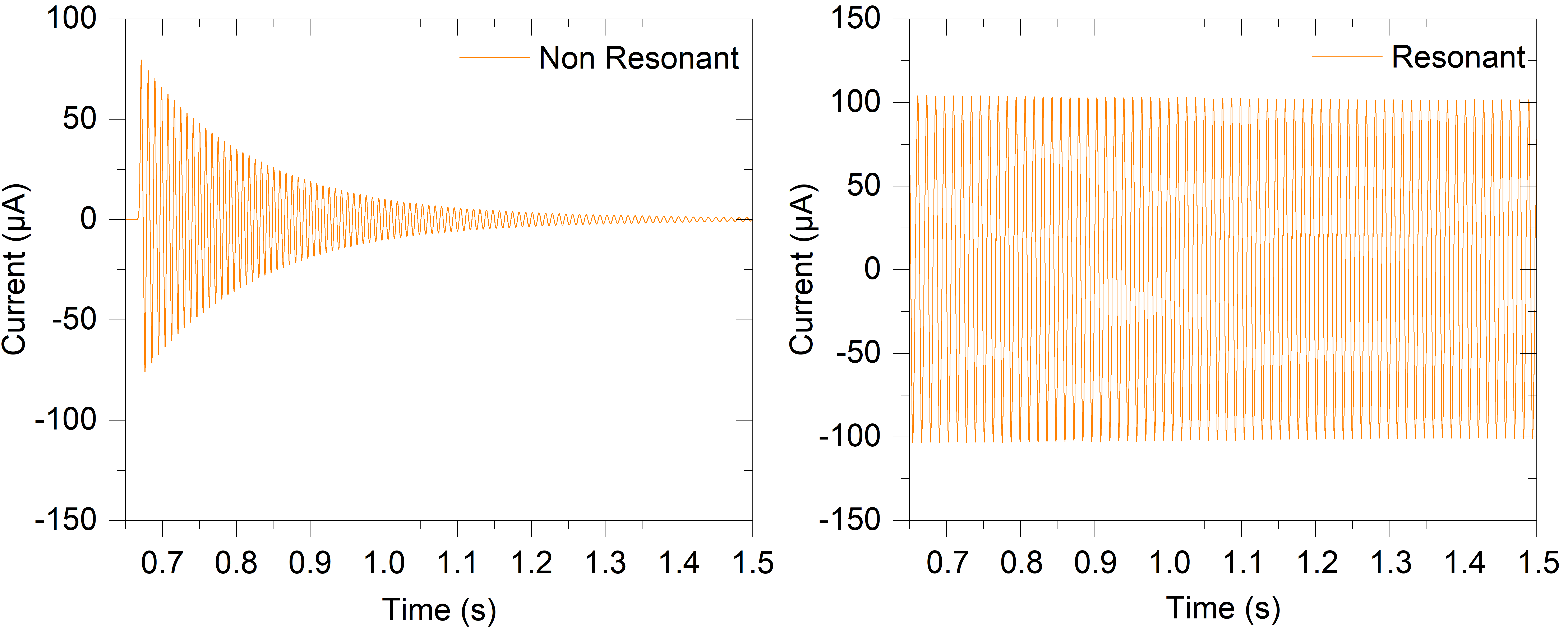

Figure 1: Thermal energy harvesting using a ferromagnetic SMA cantilever. (a) Initial state: Below the transformation temperatures (Martensite finish temperature Mf and Curie-temperature TC) the material is in martensitic and ferromagnetic state. Here, the magnetic attraction force Fferro dominates. (b) End state: Above the transformation temperatures (Austenite finish temperature Af and Curie-temperature TC) the material is in austenitic and paramagnetic state. Here the reset force FAustenite dominates. (c) Demonstrator of the thermal energy harvester with ferromagnetic SMA Ni-Mn-Ga. The energy harvesting output can be enhanced by utilizing a unique mode known as resonant self-actuation. This mode of operation prevents oscillation decay, ensuring the device operates optimally and generates maximum output. Figure 2a illustrates the output of a TMG in non-resonant self-actuation, while Figure 2b depicts the output with resonant self-actuation.

Achieving resonant self-actuation requires synchronization of the device's thermal and mechanical cycles of oscillation. For this purpose, brass cantilevers are fabricated and ferromagnetic material is applied to the tip of each cantilever. Additionally, a micro pick-up coil is integrated at the base of the tip. Figures 2a and 2b provide a visual representation of the TMG's operation concept, while Figure 2c displays a device in action. By using this concept, maximum power per footprint of up to 50µW/cm² has been demonstrated.

|

||

|

Thermal energy harvesting demonstrator device, build up from a ferromagnetic SMA cantilever with a coil attached to its tip. Download video: MP4 format, 18.2 MB |

Thermal energy harvesting with metamagnetic SMAs

Metamagnetic SMAs show a large change of magnetization during martensitic phase transformation. This effect is used here for energy harvesting. The working principle is shown in Figure 2. A polyimide (PI) cantilever of 2 x 5 mm2 in lateral size and 25 µm in thickness is fixed at its back end to a substrate. A movable mass of additional metamagnetic material is mounted at the front end. A heat source is placed below the cantilever, while a miniature magnet is placed above it. In initial position, the material is in martensitic and non-magnetic state (Figure 2(1)). When contacting the heat source, the metamagnetic SMA material attached to the front end of the cantilever heats up and transforms to the austenitic and ferromagnetic state (Figure 2(2)). Thereby, the magnetic attraction force strongly increases and the cantilever deflects out of plane (Figure 2(3)). Thus, the material cools and transforms back to the low-temperature martensitic phase. Consequently, it loses its magnetization and is reset by the polyimide cantilever to the heat source. Thus, periodic heating and cooling results in an oscillatory cantilever motion. The motion of the cantilever tip leads to a magnetization change in the pick-up coil that is placed between metamagnetic SMA material and cantilever. This results in an induced electric current, which can be used to charge a battery. Figure 4 shows a typical current signal. The thermal cycle takes about 1 s in this case. By exciting resonant eigenoscillations, much higher mechanical cycle times can be reached leading to higher current output.

|

|

Figure 2: Thermal energy harvesting using metamagnetic SMA material, which is mounted together with a pick-up coil at the front end of a polyimide (PI) cantilever. (1) Initial state: At temperature T1 below the phase transformation temperature, the material is in martensitic and non-magnetic state (magnetization M1). (2) Intermediate state: At temperature T2 above the transformation temperature, the material is in austenitic and ferromagnetic state (magnetization M2). Therefore, the magnetic attraction force strongly increases. (3) End state: The cantilever tip is in deflected state and cools below the transformation temperature. |

|

|

|

|

Figure 3: (a) Demonstrator of the thermal energy harvester using a metamagnetic SMA. (b) Time-resolved current signal induced in the moving coil. |

||

|

Thermal energy harvesting demonstrator device with metamagnetic SMA-Material on the tip. Download video: MP4 format, 15.4 MB |

Vibration energy harvesting based on magnetic SMAs

Single crystals of magnetic shape memory alloys also show the inverse magnetic shape memory effect: the reorientation of magnetic moments due to mechanical stress (Villari effect). This effect can be used for energy harvesting of kinetic vibration energy. The operation principle is shown in Figure 4. The magnetic SMA is put into the homogeneous magnetic field (biasing field) of a Helmholtz coil. Therefore, in initial state, all magnetic moments and the martensite variants coupled to them are oriented in preferred direction. Thereby, the magnetization reaches its maximum value. Upon mechanical loading the material in the direction perpendicular to the magnetic field, the martensitic variants are reoriented. Due to magnetic anisotropy, the magnetic moments are reoriented as well. Hence, the magnetization strongly decreases and reaches its minimum value. Thus, vibrations in the environment can be used to periodically deform the material and thereby periodically change its magnetization. The magnetization change ∆M induces a current in the pick-up coils, which can be used to charge a battery.

|

|

Figure 4: Schematic of vibration energy harvesting using a magnetic SMA. (a) Initial state: In the magnetic field of a Helmholtz coil, all magnetic moments and martensite variants are oriented in field direction. (b) Upon mechanical loading in direction perpendicular to the magnetic field, the martensite variants and thereby the magnetic moments are reoriented. (c) Magnetization characteristics in direction along the easy and hard axis of the magnetically anisotropic material: The resulting change of magnetization due to reorientation of the magnetic moments ∆M is indicated. |

|

|

Figure 5: Demonstrator for vibration energy harvesting using a magnetic SMA comprising a magnetic circuit, |

|

Detailed view of the Ni-Mn-Ga material in the vibrational energy harvesting demonstrator. Download video: MP4 format, 240 KB |

Publication List

- Joseph, J., Fontana, E., Devillers, T., Dempsey, N.M., and Kohl, M. (2023). A Gd‐Film Thermomagnetic Generator in Resonant Self‐Actuation Mode. Adv Funct Ma-ter, 2301250. doi:10.1002/adfm.202301250.

- Joseph, J., Ohtsuka, M., Miki, H., and Kohl, M. (2022). Thermal processes of miniature thermomagnetic generators in resonant self-actuation mode. iScience 25, doi:104569.10.1016/j.isci.2022.104569.

- Joseph, J., Wehr, M., Miki, H., Ohtsuka, M., and Kohl, M. (2021). Coupling Effects in Parallel Thermomagnetic Generators Based on Resonant Self-Actuation. In: 2021 21st International Conference on Solid-State Sensors, Actuators and Mi-crosystems (Transducers) (IEEE), pp. 463–466. doi:10.1109/Trans-ducers50396.2021.9495569.

- Joseph, J., Ohtsuka, M., Miki, H., and Kohl, M. (2021). Lumped Element Model for Thermomagnetic Generators Based on Magnetic SMA Films. Materials 14, 1234. doi:10.3390/ma14051234.

- Joseph, J., Ohtsuka, M., Miki, H., and Kohl, M. (2020). Upscaling of Thermomag-netic Generators Based on Heusler Alloy Films. Joule 4, 2718–2732. doi:10.1016/j.joule.2020.10.019.

- Kohl, M., Joseph, J., and Seigner, L. (2022). Energy Harvesting Using Magnetic Shape Memory Alloys. In: Encyclopedia of Smart Materials (Elsevier), pp. 96-103. doi:10.1016/B978-0-12-815732-9.00040-1.

- M. Gueltig, F. Wendler, H. Ossmer, M. Ohtsuka, H. Miki, T. Takagi, and M. Kohl, High-Performance Thermomagnetic Generators Based on Heusler Alloy Films, Adv. Energy Mater. 2016, 1601879, DOI: 10.1002/aenm.201601879.

- M. Gueltig, H. Ossmer, M. Ohtsuka, H. Miki, K. Tsuchiya, T. Takagi, and M. Kohl, “High Frequency Thermal Energy Harvesting Using Magnetic Shape Memory Films,” Adv. Energy Mater., vol. 4, no. 17, p. 1400751, 2014.

- M. Kohl, R. Yin, V. Pinneker, Y. Ezer and A. Sozinov, A miniature energy harvesting device using martensite variant reorientation, Mat. Sci. Forum 738-739 (2013) 411-415.