LIGA uses deep X-ray lithography with synchrotron radiation for the production of high aspect ratio polymer microstructures. By shadow printing an X-ray mask is copied into an X-ray sensitive resist. A chemical developer dissolves the irradiated areas. Free lateral shape, structures heights from several µm up to several millimetres, vertical sidewalls with optical quality (Ra < 20 nm) and sub µm structure details are the basic characteristics of this process step.

The microstructure laboratory at KARA consists of three beamlines for deep x-ray lithography, each dedicated to a specific task in the LIGA-process. In this chapter we present the LIGA3 (Litho3) beamline, dedicated to the full range of X-ray lithography capabilities (XRL, DXRL and UDXRL). The typical data for the structural height ranges from several µm to about 5000 microns with a smallest width of 1 to 20 µm. Smaller line widths as well as higher structures are design dependent and therefore under further development. The whole system is under development.

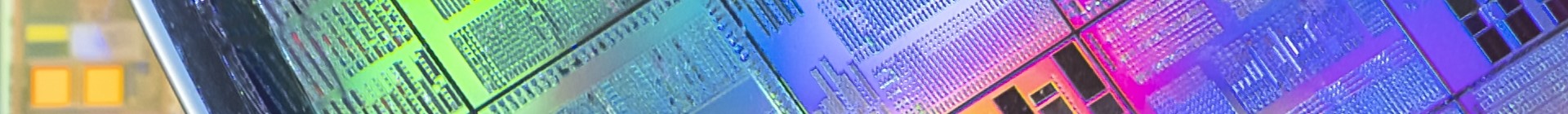

The whole laboratory is placed inside a clean room for accurate environment conditions. The experimental equipment, together with the microstructure fabrication capabilities at IMT/KIT, is a unique installation for high precision and high aspect ratio microstructure fabrication. Even the resist preparation, development and optional electroforming process is done by using the clean room capabilities and expertise of IMT.