Advanced Manufacturing and Printing

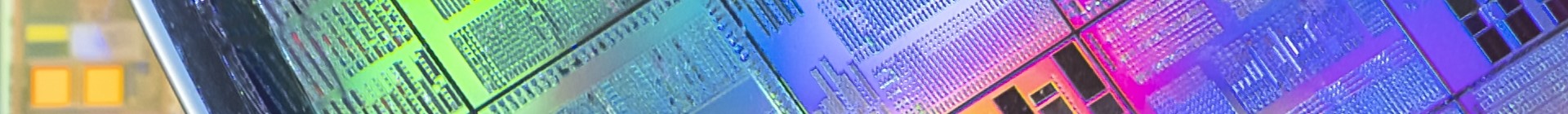

The shaping of functional materials at the highest achievable resolution is a highly dynamic endeavour that benefits from advances in photonics, chemistry, and a wide range of material deposition processes.

Additive manufacturing is especially interesting for its ability to avoid waste. Molecular assembly can span the length scales and achieve large area coverage. Modern materials science breaks with convention to yield functional materials that start as resists and achieve unusual functionality. The patterning of heterogeneous materials over all length scales achieve previously unheard of functionality through metamaterial arrangements. At IMT we pay particular attention to upscaling towards macroscale applications.

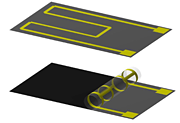

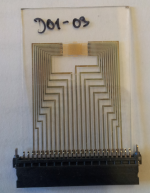

Microfabrication processes are optimised to work on planar substrates. To take advantage of the high surface to volume ratio of Microstructures and fluidics, three-dimensional sensor and actuator structures are needed. Therefore, devices are designed and fabricated on planar substrates using inkjet printing, that gain functionality once the substrates are rolled up to a cylindrical shape.

Rolled-up MR Coils (J. G. Korvink)

Structuring for Rolled-up MEMS (D. Mager)

Besides sufficient analytical capabilities, sensors for real life consumer applications have to be very cheap. Therefore, their design should be as simple as possible leading in only a few production steps keeping costs of fabrication low. As the universal smell sensor under development should meet these requirements its electrode structure is fabricated by inkjet printing technology. Testing analytical performance and long term stability is actually under progress.